A bilge pump is an important tool found on almost every boat. It helps new boat owners especially, who might wonder, “What is a bilge pump?”

Its main job is to get rid of water that ends up at the bottom inside part of the boat, known as the bilge. This water might get there in several ways:

- It could be rain or sea spray that gets inside;

- Water used for cleaning the boat that gathers there;

- Or water from coolers inside the boat that drains into the bilge. On big boats, things like coolers, the edges of big openings, and even places to put drinks might have drains that let water out of the boat. But on smaller boats, this water goes to the bilge. Water can also come from small leaks, like water leaking around the engine area in some boats.

Most boats don’t have a big enough bilge pump to stop the boat from sinking if there’s a big hole. But, the pump can give you extra time to fix the leak, ask for help, or get ready to leave the boat safely if needed.

Where are Bilge Pumps Located on the Boat?

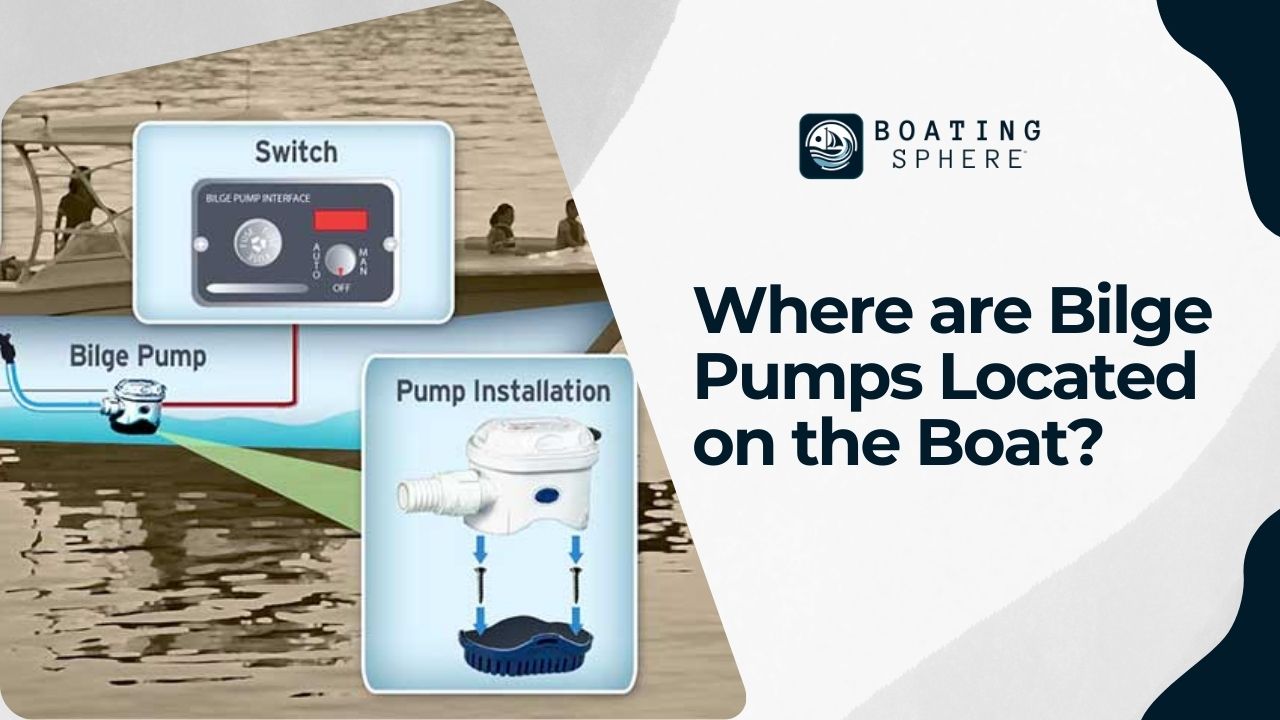

Every boat must have a pump or bilge pump intake positioned at the bilge’s lowest part. Boats of larger size require a pump capable of holding water in every sealed compartment. The discharge outlets should be placed at least eight inches above the waterline for efficiency.

It’s crucial for all bilge pumps aboard to be within easy reach. This accessibility allows for the inspection of the pump and its float mechanism and facilitates the removal of any blockages around the pump intake. Should a pump be situated in a hard-to-access area, like beneath the engine in a sterndrive boat, moving it to a more reachable location is advisable.

How and When Do You Turn on the Bilge Pump?

The pump might be equipped with a float or switch for automatic activation when water accumulates in the bilge, which is crucial for boats moored in water to ensure activation post-heavy rainfall. A manual switch might also be at the helm, often featuring settings for both “auto” and “manual” operations.

It’s vital to regularly clean the pump’s surrounding area of debris to prevent clogging or pump damage. This is particularly essential for new boats, where construction remnants like sawdust, fiberglass particles, foam, epoxy, and even screws may accumulate in the bilge.

Ensure the float switch is periodically inspected for signs of wear or corrosion.

To avoid moisture damage, bilge pump wiring should be installed above the bilge area, ensuring all connections are waterproof. If the pump seldom operates, test its functionality by introducing a small amount of water into the bilge, verifying the switch’s operation and the pump’s water removal capability.

Choosing the Best Bilge Pump

A bilge pump’s efficiency is measured in gallons per hour (GPH), though its actual performance typically reaches about 60% of its rated capacity. Factors like the water’s lift height, distance, and the type of discharge hose used significantly influence the effective pumping rate.

Switching from a corrugated to a smooth-wall discharge hose can boost the flow rate by as much as 30%. Contrary to what might seem intuitive, smaller boats require pumps with higher flow ratings due to quicker filling during incidents like hull breaches than larger vessels.

Savvy boaters employ a dual-pump setup for optimal safety, particularly when venturing far offshore. This includes a smaller automatic bilge pump (400-500 GPH) installed at the bilge’s lowest point for managing minor water ingress and a larger capacity pump (3,500 GPH) positioned higher up, ready to tackle severe flooding.

Was this page helpful?